Semi Truck Scales For Sale: A Comprehensive Guide to Weighing Your Options

Introduction: The Foundation of Compliance and Efficiency

In the dynamic world of trucking and logistics, accuracy and compliance are paramount. Overloaded vehicles pose significant safety risks, lead to hefty fines, and can damage infrastructure. This is where semi-truck scales, also known as truck scales or weighbridges, come into play. They provide a crucial service by accurately determining the weight of semi-trucks and their cargo, ensuring adherence to legal weight limits and optimizing operational efficiency. If you're in the market for "Semi Truck Scales For Sale," this comprehensive guide will walk you through everything you need to know, from understanding different types and benefits to navigating the purchasing process and ensuring long-term performance.

Semi Truck Scales For Sale: A Comprehensive Guide to Weighing Your Options

I. Why Invest in Semi Truck Scales? The Benefits Unveiled

Investing in a semi-truck scale offers a multitude of advantages, extending far beyond simply avoiding overweight fines.

- Compliance with Regulations: Federal, state, and local regulations dictate strict weight limits for commercial vehicles. Exceeding these limits can result in substantial fines, potential legal repercussions, and delays in delivery schedules. Truck scales ensure compliance and protect your business from unnecessary penalties.

- Enhanced Safety: Overloaded trucks are prone to accidents due to compromised braking systems, reduced maneuverability, and increased wear and tear on tires and other components. Accurate weighing helps prevent these safety hazards, protecting drivers, cargo, and the general public.

- Optimized Load Management: Truck scales allow for precise load distribution, maximizing cargo capacity without exceeding legal limits. This optimization improves fuel efficiency, reduces maintenance costs, and increases overall profitability.

- Inventory Control and Accuracy: For businesses involved in buying and selling bulk materials, truck scales provide accurate weight measurements for inventory management and billing purposes. This minimizes discrepancies and ensures fair transactions.

- Preventative Maintenance: Monitoring vehicle weight can help identify potential mechanical issues early on. For instance, uneven weight distribution might indicate suspension problems or axle misalignment, allowing for timely repairs and preventing costly breakdowns.

- Improved Operational Efficiency: By streamlining the weighing process, truck scales reduce turnaround times and improve the overall efficiency of trucking operations.

II. Types of Semi Truck Scales: Choosing the Right Fit for Your Needs

Semi-truck scales come in various configurations, each with its own set of advantages and disadvantages. Understanding the different types is crucial for selecting the scale that best suits your specific requirements.

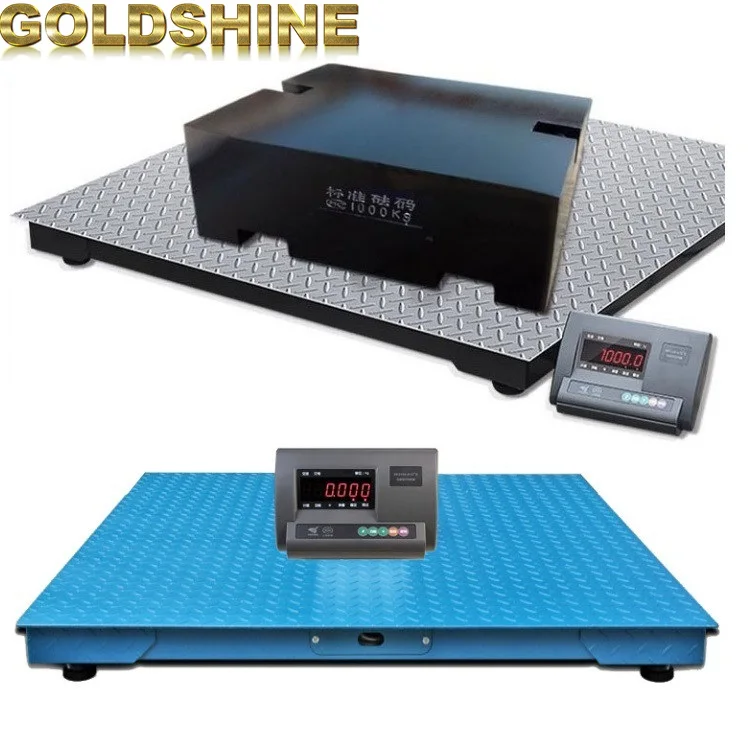

- Above-Ground Scales: These scales are installed on a concrete foundation at ground level. They are relatively easy to install and maintain, making them a popular choice for many applications. However, they require a significant amount of space and can be more susceptible to damage from the elements.

- Pit Scales (In-Ground Scales): Pit scales are flush with the surrounding ground, requiring excavation and the construction of a pit. They offer a more aesthetically pleasing appearance and are less prone to damage from forklifts or other equipment. However, they are more expensive to install and maintain due to the complexity of the pit construction.

- Portable Scales: Portable scales are designed for mobility and can be easily transported to different locations. They are ideal for temporary weighing applications or situations where a permanent scale is not feasible. Portable scales typically have a lower weight capacity than permanent scales.

- Axle Scales: Axle scales weigh each axle individually, providing detailed information about weight distribution. They are commonly used for enforcement purposes and for monitoring weight distribution on specialized vehicles.

- Wheel Load Scales: Wheel load scales are similar to axle scales but weigh individual wheels. They are useful for identifying uneven weight distribution across an axle.

- Static Scales: Static scales require the vehicle to be stationary while being weighed. They offer the highest level of accuracy but can be slower than dynamic scales.

- Dynamic Scales (Weigh-in-Motion Scales): Dynamic scales allow vehicles to be weighed while in motion, increasing throughput and reducing turnaround times. However, they are generally less accurate than static scales.

III. Key Considerations When Purchasing Semi Truck Scales

Before investing in a semi-truck scale, carefully consider the following factors to ensure you select the right equipment for your needs:

- Weight Capacity: Determine the maximum weight you need to weigh. Choose a scale with a weight capacity that exceeds your heaviest loads by a comfortable margin.

- Scale Length and Width: Ensure the scale is long and wide enough to accommodate the longest and widest vehicles you need to weigh.

- Accuracy: Accuracy is paramount for legal compliance and accurate inventory management. Choose a scale with a high level of accuracy, typically expressed as a percentage of full scale.

- Durability and Construction: Truck scales are subjected to heavy loads and harsh environmental conditions. Choose a scale constructed from durable materials, such as steel or concrete, and designed to withstand the rigors of daily use.

- Location and Space Constraints: Consider the available space and site conditions when choosing the type of scale. Above-ground scales require more space than pit scales. Portable scales offer the greatest flexibility in terms of location.

- Features and Functionality: Look for features that enhance efficiency and data management, such as digital displays, printers, data logging capabilities, and connectivity options.

- Calibration and Maintenance: Regular calibration is essential for maintaining accuracy. Choose a scale that is easy to calibrate and maintain.

- Warranty and Support: Select a reputable manufacturer or supplier that offers a comprehensive warranty and reliable technical support.

- Price: Semi-truck scales vary significantly in price depending on the type, size, features, and manufacturer. Obtain quotes from multiple suppliers and compare prices carefully.

- Software Integration: Determine if the scale needs to integrate with existing accounting, inventory, or logistics software.

IV. Installation and Maintenance: Ensuring Long-Term Performance

Proper installation and regular maintenance are crucial for ensuring the accuracy, reliability, and longevity of your semi-truck scale.

- Professional Installation: Hire a qualified contractor with experience in installing truck scales. Proper installation is essential for ensuring accurate weighing and preventing premature failure.

- Regular Calibration: Calibrate the scale regularly, typically every six months to one year, or more frequently if required by local regulations.

- Routine Maintenance: Inspect the scale regularly for signs of damage or wear. Clean the scale platform and load cells to remove debris and prevent corrosion.

- Load Cell Inspection: Inspect load cells for damage, corrosion, or misalignment. Replace any damaged or malfunctioning load cells promptly.

- Software Updates: Keep the scale's software up to date to ensure optimal performance and security.

V. Potential Challenges and Solutions

- Challenge: Inaccurate Readings due to Debris or Interference.

- Solution: Implement a regular cleaning schedule and ensure the scale is free from obstructions.

- Challenge: Load Cell Failure.

- Solution: Perform regular load cell inspections and replace damaged or malfunctioning load cells promptly.

- Challenge: Environmental Factors (Temperature Fluctuations, Moisture).

- Solution: Choose a scale designed to withstand the local climate and protect sensitive components from moisture and temperature extremes.

- Challenge: Software Glitches or Connectivity Issues.

- Solution: Keep the scale's software up to date and ensure proper network connectivity.

VI. Semi Truck Scales For Sale - Price Table

| Scale Type | Capacity (lbs) | Platform Size (ft) | Features | Approximate Price Range |

|---|---|---|---|---|

| Above-Ground | 100,000 | 10x70 | Digital Indicator, Printer Connectivity, Steel Construction | $20,000 - $40,000 |

| Pit Scale | 120,000 | 10x70 | Digital Indicator, Printer Connectivity, Concrete Foundation Required | $30,000 - $55,000 |

| Portable Scale | 40,000 | Axle-Based | Wireless Connectivity, Lightweight Design, Battery Powered | $5,000 - $15,000 |

| Axle Scale | 20,000 per axle | N/A | Individual Axle Weight Readings, LCD Display | $3,000 - $8,000 |

| Weigh-in-Motion Scale | 100,000 | 10x70 | High-Speed Weighing, Data Integration, Requires Specialized Installation | $40,000 - $70,000+ |

VII. Frequently Asked Questions (FAQ)

- Q: How often should I calibrate my truck scale?

- A: Typically, every six months to one year, or more frequently if required by local regulations.

- Q: What is the difference between an above-ground and a pit scale?

- A: Above-ground scales are installed on a concrete foundation at ground level, while pit scales are flush with the surrounding ground, requiring excavation and the construction of a pit.

- Q: Can I install a truck scale myself?

- A: It is highly recommended to hire a qualified contractor with experience in installing truck scales to ensure proper installation and accurate weighing.

- Q: What is the lifespan of a truck scale?

- A: With proper maintenance, a truck scale can last for 10-20 years or more.

- Q: What factors affect the accuracy of a truck scale?

- A: Factors such as debris, temperature fluctuations, improper installation, and load cell failure can affect the accuracy of a truck scale.

Conclusion: Weighing in on Success

Investing in the right semi-truck scale is a strategic decision that can significantly impact your business's bottom line and ensure compliance with regulations. By carefully considering your specific needs, understanding the different types of scales available, and following best practices for installation and maintenance, you can choose a scale that provides accurate, reliable, and long-lasting performance. Remember to prioritize safety, compliance, and efficiency when making your decision. A well-chosen semi-truck scale is not just an expense; it's an investment in the future of your operations. As technology advances, consider scales with advanced features like cloud connectivity and remote monitoring for even greater efficiency and data-driven decision-making.